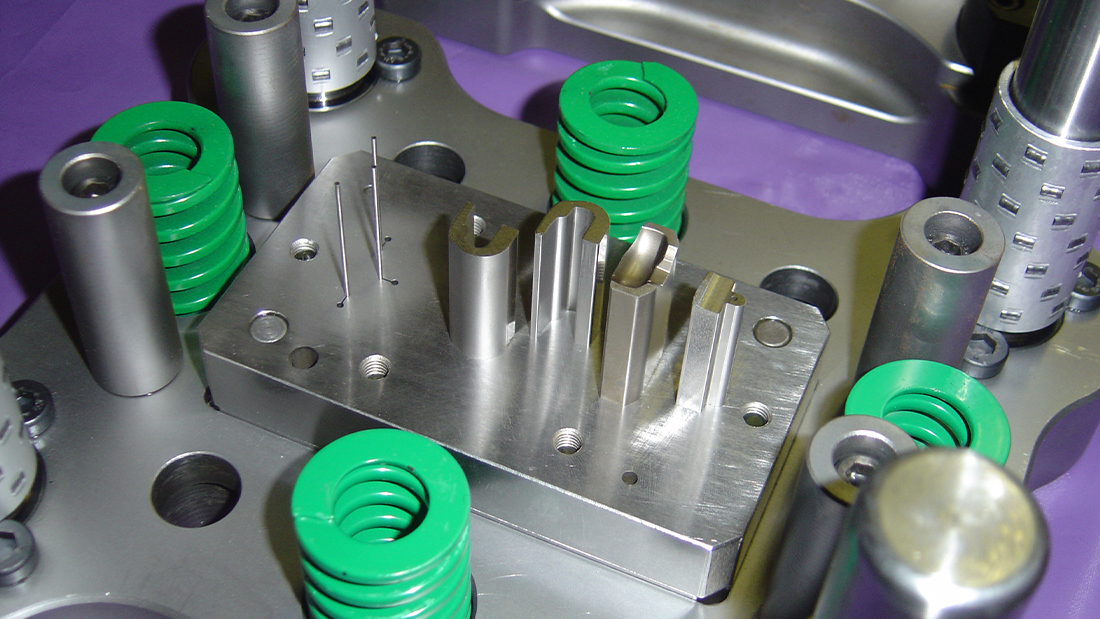

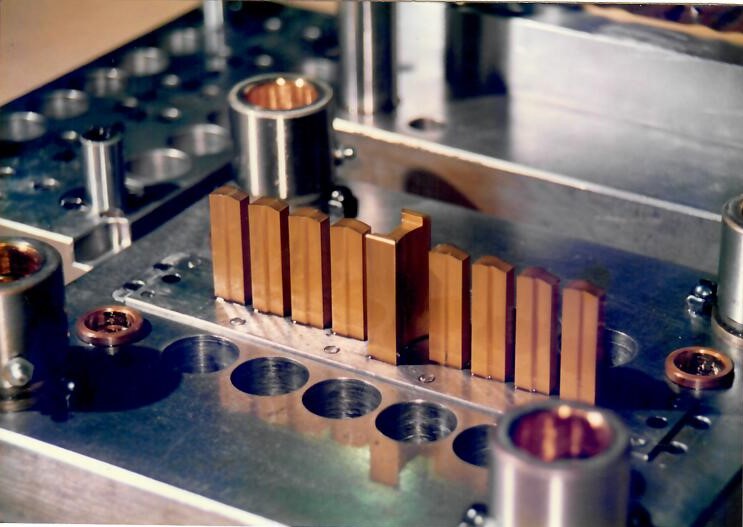

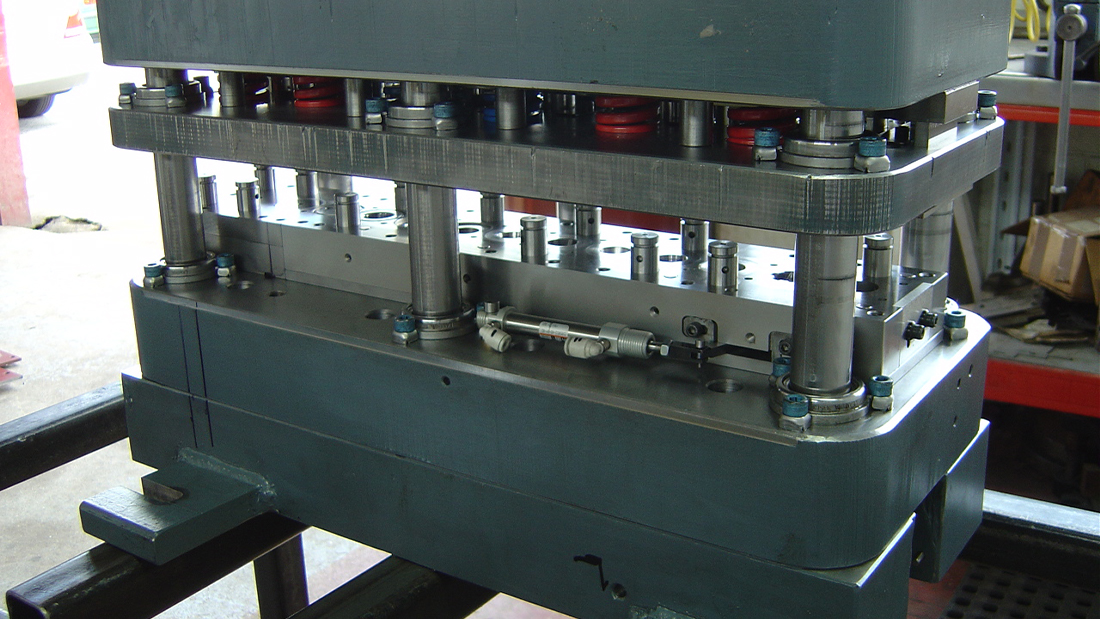

Our core business is the design and manufacturing of new tools including automation and custom Tooling. Our in-house designers can model the tools as per requirement for any modern or complex production strategies necessary.

Existing tools can be modified for many reasons including to reduce wastage or improve efficiency. These modifications are completed based on the requirements of the production process, careful study of existing designs and the overall specifications of the component produced.

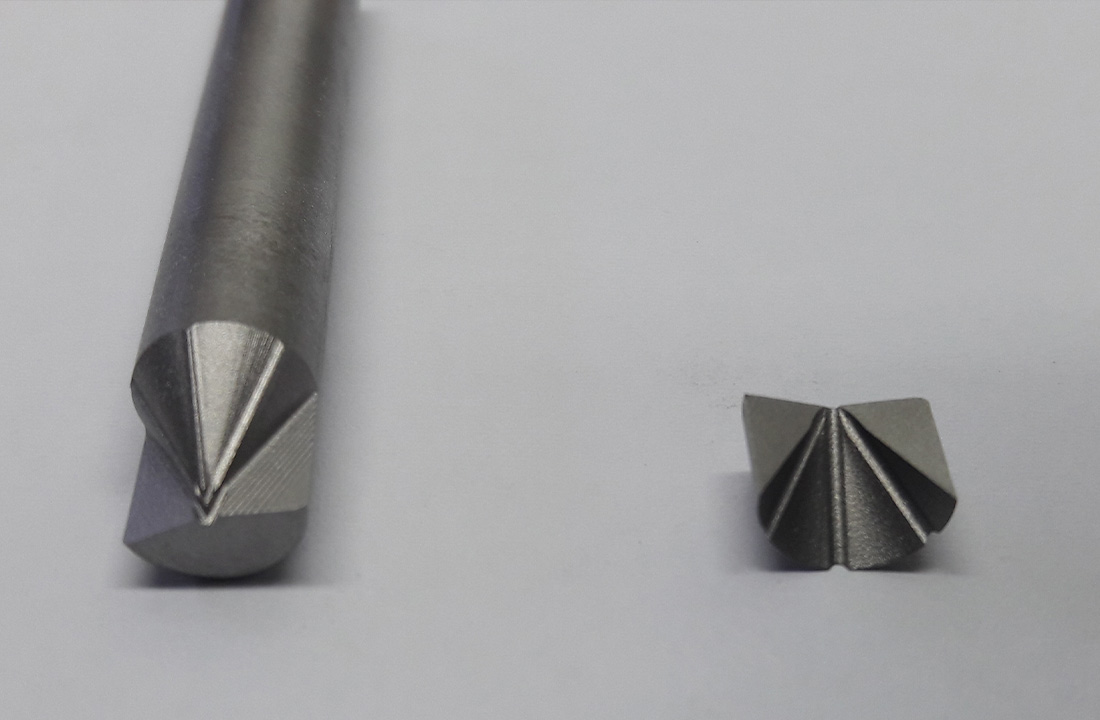

The re-productions of worn-out dies, strippers and punches are generally an easy fix in our production facilities with or without the original designs. The resulting solutions are generally digitized allowing us to provide a seamless flow of information and repeatability.

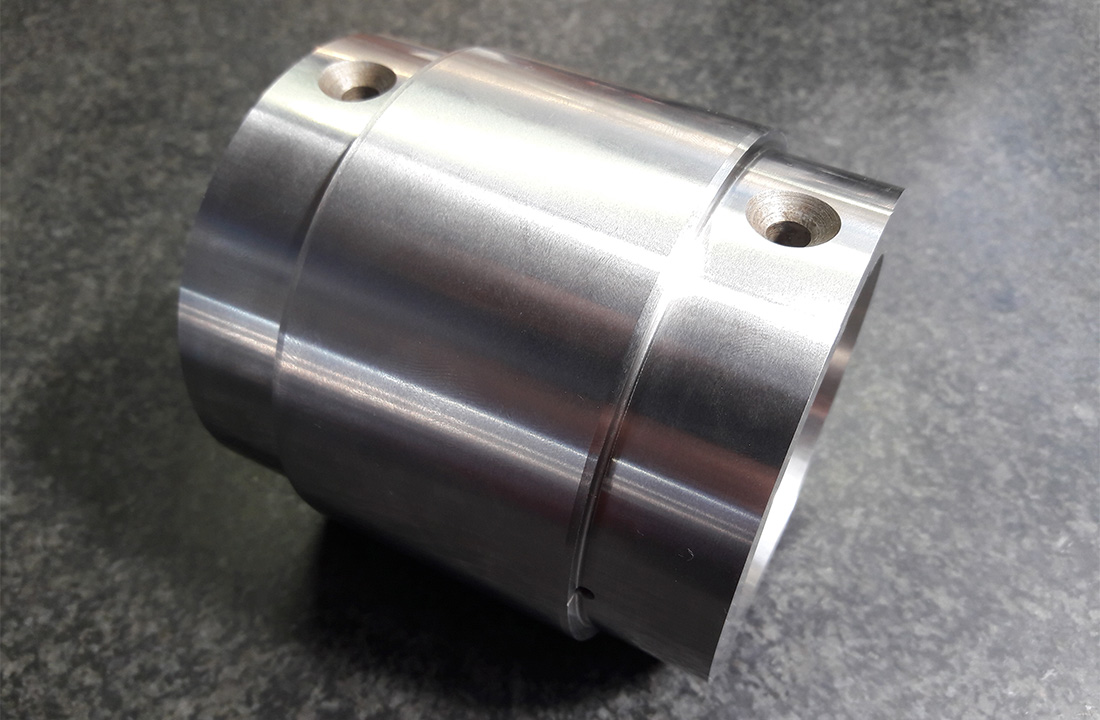

We use high quality CNC machines in our manufacturing division. This includes, 5 axis Mills, Lathes and EDM machines with varying capacities. The maximum work piece capacity of 3 Ton enables us to offer a large diversity of machining capabilities.

Our grinding facilities include:

Grinding is used to produce our fine finishes and close tolerances.

Our pressing facilities include 100 ton C frame press with Pneumatic Clutch variable stroke and die cushion and a 40 ton C frame press with Pneumatic Clutch, coil feeder, press speed 75 or 150 strokes per minute with variable stroke, and Die Cushion. This enables us to test tooling with a range of production scenarios also complements purpose-built tools, catering to low and high volumes of pressed parts.